How to solve dampness in skirting boards

Civil work

Edification

SoluciónHow to solve dampness in skirting boards

Descripción sistema

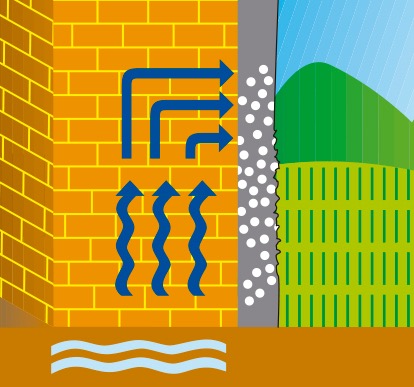

The degradation of the lower parts of the walls due to rising damp from the foundations is one of the most common construction pathologies in dwellings.

Moisture from the ground penetrates the foundation and rises through it to the upper walls by capillary action. The salts carried away during this process are deposited on the inside of the wall and on the plaster.

The continuous presence of water and humidity in the wall causes the hydration and increase in volume of these salts, which leads to the destruction of the wall and the plaster.The faster the phenomenon occurs, the greater the quantity of water and salts present in the system.

The solution consists of usingPROPAM® CAL SEC, a water-repellent mortar, impermeable to rainwater, with a highly decorative finish and very easy to apply, which makes it possible to renovate walls affected by damp and efflorescence, as well as to prevent damp in new buildings.

Linked solutions

- WATERPROOFING NEW CONSTRUCTION FOUNDATIONS

- WATERPROOFING A SWIMMING POOL

- WATERPROOFING A CELLAR, GARAGE, WALL, LIFT SHAFT…

- CREATE A CHEMICAL BARRIER AGAINST HAIR REGROWTH

- HOW TO SEAL WATERWAYS CORRECTLY

- INSTALLING GLASS WOOL IN THE CHAMBER OF AN ENCLOSURE

Related products

- PROPAM® LATEX

- PROPAM® CREAM

- PROPAM® MINERALISER

- PROPAM® IMPE

- PROPAM® IMPE FLEX

Solution

PREPARATION OF THE SUBSTRATE

Remove degraded plaster and plaster at least 1 metre above the area affected by damp, until a firm and stable substrate is obtained.

In hot weather or with very absorbent substrates, it is advisable to dampen it beforehand.

Install mesh where different supports meet (columns and slabs).

On stone walls, remove the disintegrated parts to a depth of 2-5 cm and fill with the product and rubble or stones. On these walls, it is advisable to fix a galvanised mesh and apply the product withPROPAM® LATEX1:4 additive with water to improve adhesion.

On smooth or non-absorbing concrete substrates, the application ofPROPAM® GRIP +is recommended as a bonding bridge.

APPLICATION

KneadPROPAM® CAL SECwith a slow electric mixer (500 rpm) and clean water until a homogeneous, lump-free paste is obtained.

Spread the paste preferably by spraying it with a trowel on the substrate until a minimum thickness of 2 cm is achieved at any point. It can be sprayed by machine.

Finish (scraping, trowelling, dripping) when the product has the required consistency, usually between 1 and 6 hours after application. Coat with highly breathable materials that do not create a water vapour barrier.

Recommendations

- Do not apply in unventilated areas to avoid condensation.

- Apply between +5 and +35ºC temperature.

- Do not apply to surfaces with an angle of less than 10%.

- Do not apply to areas submerged in water.

- It must be 1 cm above the ground to prevent capillary rise through the product.

- Indoor capillary trapping problems can be avoided by using other products in the range. Barrier products, PROPAM® CREAM, PROPAM® MINERALISER, PROPAM® IMPE, PROPAM® IMPE FLEX

España

España  Croacia

Croacia  Turquía

Turquía  Argentina

Argentina  México

México  Colombia

Colombia  Uruguay

Uruguay  Bolivia

Bolivia  Bangladesh

Bangladesh  Túnez

Túnez